How magnetic tubes works

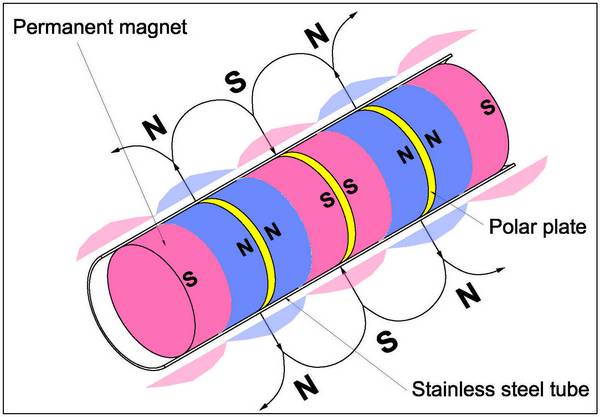

A magnetic tube made of a stainless steel tube, polar plates,end-plugs, and permanent magnets. The higher the surface gauss of the tube, the higher the price. As the permanent magnets being the most expensive parts, we will look into how unscrupulous companies reduce costs of manufacturing magnetic tubes with high surface gauss.

Method 1: Reducing thickness of the stainless steel tube

Drawback: Reduced lifespan of magnetic tubes

SS304 and SS316 stainless steels are commonly used materials used for manufacturing magnetic tubes. In the Chinese market, the thinnest SS304 tubes are between 0.45-0.50mm. If the tubes get any thinner, the lifespan of the said tubes will be drastically reduced.

Due to having fewer applications and of less comprehensive specifications, the thinnest SS316 tubes are found to be between 0.75-0.80mm. This is also why magnetic tubes made of SS316 have lower surface gauss compared to tubes made of SS304.

Companies are permitted to manufacture 0.5mm thick SS316 tubes (MOQ at 500kg) when there is a demand of stability in batches manufactured. However, some unscrupulous companies will manufacture magnetic tubes with only 0.3mm thick tubes, allowing for higher surface gauss using weaker magnets.

Method 2: Reducing volume of permanent magnets used

Drawback: Uneven tube surface leading to easy fracturing

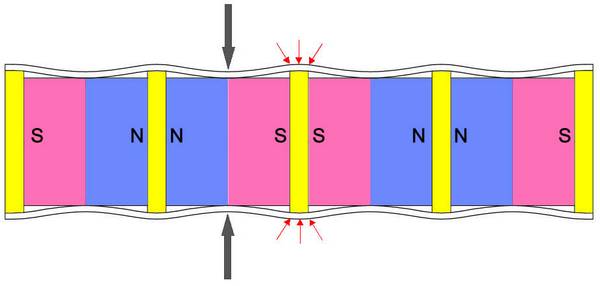

Reduced diameter of magnets as shown in the diagram below

Magnetic flux density of tubes consist of smaller magnets will not decrease by increasing the diameter of the polar plates, due to magnetic flux density tests being conducted around the circumference of the plates. However, due to lack of support from the magnets within the tube, the wall of the tube will collapse in time. Furthermore, as stress cannot be distributed evenly and focused only the plates, the tube fractures easily around the plates, rendering the entire tube unusable and in more severe cases, contaminating the materials as well.

Method 3: Using chipped and fractured magnets

Drawback: Uneven surface gauss causing loss of effectiveness easily

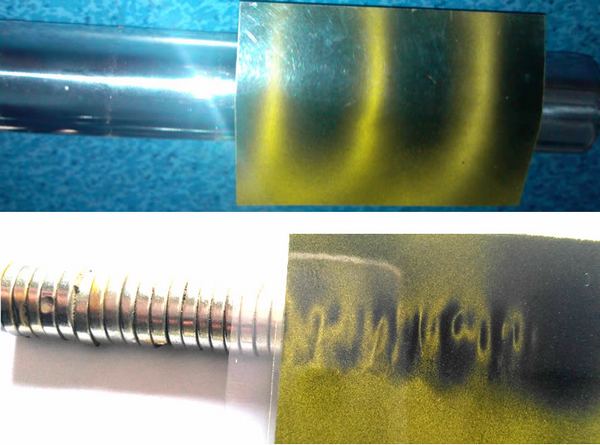

Chipped and fractured magnets are rejects. However, some unscrupulous companies will seal them in tubes regardless, as these defects are indistinguishable from the external appearance and difficult to detect as well.

Method 4: Purchasing “second grade goods”

Drawback: Tubes with uneven magnetic fields and poor consistency

The so-called “second grade goods” are magnets made by top-tier manufacturers for top-tier buyers. These products are, however, discarded rejects due to various factors. Due to being high performance products still, some unscrupulous companies will purchase them at discounted prices. However, these “second grade goods” are mostly thin pieces between 3-10mm thick. When observed with a magnetic polar viewer, these defects will present itself as shown in the following diagram.

Furthermore, these “second grade goods” have inconsistent sources. As such, there is no guarantee in the performance of the next batch purchased, resulting in poor consistency between batches.

The above mentioned methods are how costs of magnetic separations are reduced unscrupulously. Please exercise caution when purchasing magnetic tube products.